Contact Us

Tianjin Qibang Technology Development Co., Ltd

Tel:022-60307018

Address:No. 37 Cangyuan Street, Economic Development Zone, Jizhou District, Tianjin City

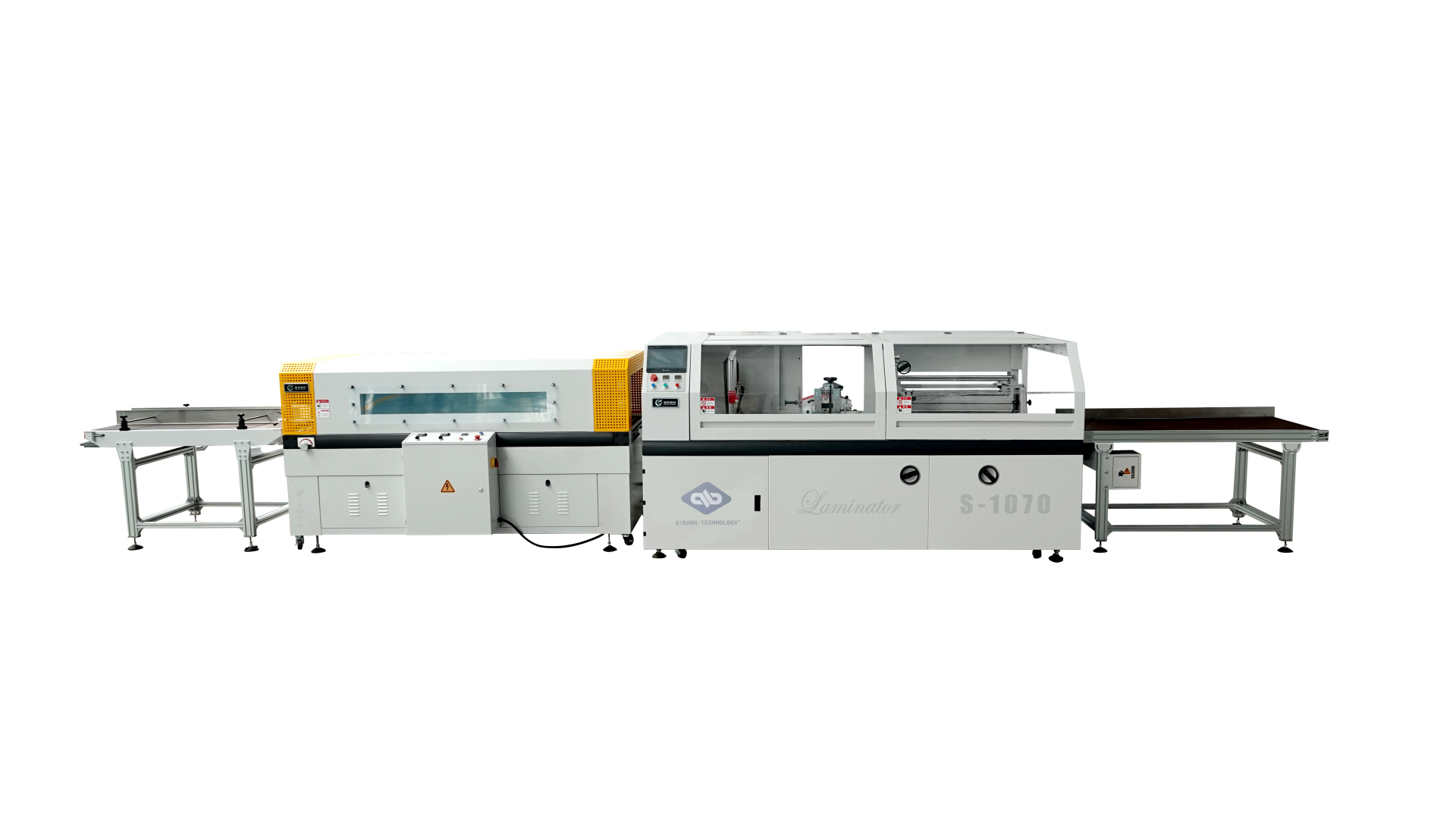

Large format shrink wrapping machine (S-1070)

author:admin time:2025-05-29

Functions:

The shrink wrapping machine is assembled by 4 units: Automatic feeding convey table, Automatic sealing and cutting machine, Heat circulating shrink tunnel,Automatic collection convey table, it`s suitable for various kinds of products.the machine mechanical speed can reach 100 packs/minute.

Advantages:

1) Machine adopts Germany Schneider control system, Japan Mitsubishi,Panasonic servo motor driver, and Germany IFM,Japan Omron electric parts.

2) The transverse sealing tool adopts reciprocating cutting, which can be freely converted to follow cutting or positioning cutting.

3)Teflon coating constant temperature single blade continuous cutting, can achieve 1m/second transmission speed, good effect, fast speed, no adhesion, continuous line, zero pollution.

4)Sealing and cutting machine conveyor table can achieve automatic expansion, seamless docking, more suitable for small packaging items.

5)Full servo control system, can achieve one-click start, interconnection and mutual control.

6)Heat circulating shrink tunnel, heat control integration, wind direction can be freely adjusted, double layer heat preservation curtain, energy saving, constant temperature, heat evenly, ensure the excellent sealing.

Parameters:

No. | Name | Description |

1 | Model | S-1070 |

2 | Packaging size | L: no limit W:60-700mm H:5-300mm |

3 | Mechanical speed | 100 pcs/min |

4 | Power | 30KW |

5 | Electric | 380V |

6 | Overall size | 9500*2100*1430mm |

7 | Weight | 3500kg |

Unit 1. Feeding conveyor

Total length of conveyor: 1500mm

Width of conveyor: 800mm

Conveying speed: 0-26m/min

Height of feed belt : 850 + 10mm

Unit 2. Automatic sealing and cutting machine

External dimensions (L*W*H): 2820 *2100 *1430 mm

Packing speed (pc/min): 100 pcs/min

Packing size (mm): L no limit; W 60-700mm; H 5-300mm

Power and power: 3 Phase AC380V. 7KW

Suitable film (UM): 0.015 ~ 0.025 thickness ( folded POF)

Unit 3. Thermal cycle shrink tunnel

Machine size (L*W*H): 2500*1100*1300 mm

Shrink tunnel size (L*W*H): 2000*1200*370mm

Conveying speed (m/min): 0-35m/minute

Power and power: 3 Phase AC380V. 22KW

Unit 4. Receiving conveyor

Total length of conveyor : 1800mm

Width of conveyor : 800mm

Conveying speed: 0-35m/min

Configurations:

Unit 1.Feeding conveyor | ||

Component | Name | Description/Brand |

Delivery system | Motors | Huichuan servo motor |

Reduction gear | Taiwan Jinhong speed reducer | |

Convey belt | PU American belts | |

Structure | Aluminum alloy structure | |

Unit 2. Automatic sealing and cutting machine | ||

Component | Name | Description |

Operating system | With man-machine interface, the operation is simple and easy, the system has automatic monitoring function, convenient maintenance | |

Control system | PLC | Japan Omron |

Touch screen | Taiwan Waylon | |

Frequency transformer | Japan Panasonic | |

Ow-voltage apparatus | Frence Schneider | |

Servo system | Japan Omron | |

Sealing and cutting system | Heat source | Stainless steel heating tube |

Sealing knife | The anti sticking temperature resistant metal sealing knife, knife external plating Teflon layer. | |

Sealing temperature control | Japanese Omron thermostat | |

Knife protection | Japanese Panasonic brand, effectively prevent the miscutting of packaging objects. | |

Longitudinal sealing cylinder and electromagnetic valve | AirTAC | |

Horizontal sealing control | The Omron servo controller enables faster, more accurate cutting and better stability than cylinder control | |

Waste film recycling system | Motor | Taiwan Hanshin brand ensures accurate and uniform recycling of waste materials |

Frequency converter | The Panasonic brand of Japan controls the recycling speed according to the packaging speed | |

Inductive switch | Japan Panasonic brand accurate control of recycling waste time, positive gas brand position switch can realize the slow start and stop of film collection, residual film can be better collected and disassembled | |

POF transfer system | Motor | The brand of North translation ensures the smooth delivery of film |

Inductive switch | Japan Panasonic brand to ensure the rapid start and stop of the film, positive brand position control switch, can accurately control the speed of the film to achieve the smooth acceleration and deceleration of the film | |

Frequency transformer | Japanese Panasonic brand, control film speed | |

Delivery system | Belt | PVC conveyor belt |

Motor | Japan Omron servo motor to ensure smooth transmission | |

Driver | Japan Omron servo drive | |

Detection | Japan Omron, Japan Panasonic photoelectric sensor, accurate and sensitive detection products | |

Punch | Stainless steel multi hole puncher, so that the air in the bag can be rapidly discharged when contracting | |

Mechanism material | Color is ship grey carbon steel spray | |

Unit 3. Thermal cycle shrink tunnel | |||

Component | Name | Description | |

Heating system | Heating source | stainless steel heating tube, long service life | |

Insulating layer | Made of high temperature resistant rock wool, low surface temperature during operation, reduce heat loss. | ||

Temperature control | Omron high-end thermostat | ||

Delivery system | Motor | Taiwan Sheng Bang brand reducer | |

Frequency transformer | Japan Panasonic brand to ensure smooth delivery | ||

Air distribution system | Brazil WEG fan motor adopts advanced lower air handling technology. The air volume is directly regulated by frequency converter, and the wind direction and the air volume at the bottom can be adjusted by the handle, which can make full use of heat energy, reduce energy consumption and improve energy efficiency | ||

Control system

| Power switch | Taiwan Tend brand | |

Auxiliary relay | Japanese Omron or Schneider brand | ||

Thermostat | Omron high-end thermostat automatic PID control | ||

Emergency stop | French Schneider brand | ||

Structure | Outer plate | The use of carbon steel plate by bending, surface spray treatment. Color: grey ship. | |

Inner plate | Galvanized plate hydraulic production | ||

Unit 4.Receiving conveyor | ||

Component | Name | Description |

Delivery system | Motor | OT brand |

Conveyor belt | PU American belts | |

Structure | Aluminum alloy structure | |